Reactive Metals

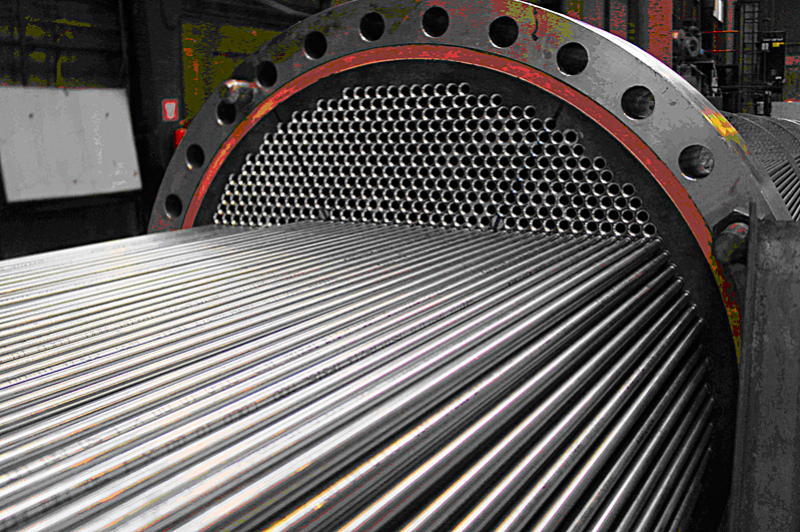

The Rasmussen Company specializes in custom corrosion resistant process equipment, including heat exchangers, from titanium, nickel alloys, tantalum, niobium, or zirconium.

Equipment made from noble metals offer a number of benefits, including:

· Superior corrosion resistance. Formation of natural oxide film enhances corrosion resistance

· Thinner walls for better heat transfer

· Reduced repairs and maintenance

· Cross contamination prevention. Tell-tale port construction acts exactly like double tubesheet designs to eliminate the possibility of cross contamination.

· Complete drainability. Flushmount tubesheet technology eliminates liquid hold-up, assuring complete drainability. Flush times are greatly reduced for increased productivity.

Titanium Heat Exchangers

Titanium heat exchangers are typically used in, but not limited to, applications involving chlorides and hydroxides used in bleaching processes in the paper industry, oxidative environments, nitric acids, and chromic acids. Titanium is also virtually inert to the effects of salt water.

Nickel Alloy Heat Exchangers

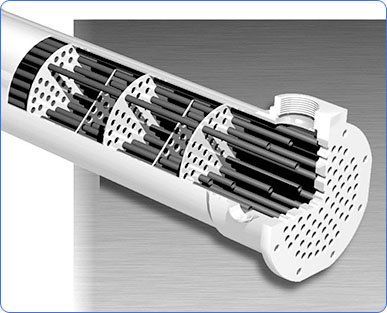

Nickel alloys exhibit exceptional corrosion resistance and strength in a wide variety of applications. Nickel alloys are suitable for a wide variety of applications due to the many different compositions and properties associated with the different alloys. The Rasmussen Company specializes in shell and tube type heat exchangers, . Contact the Rasmussen Company with your inquiry for custom equipment made from a nickel alloy.

Tantalum Heat Exchangers

The Rasmussen Company also specializes in custom heat exchangers made from tantalum. The most common are shell and tube type heat exchangers, but others types, such as immersion heating coils, are available. Tantalum is extremely corrosion resistant in a wide variety of demanding environments including nearly all organic and inorganic compounds in the pharmaceutical and chemical process industries.

Its advantages include:

· Superior corrosion resistance. Inert in almost all environments up to temperatures of 450°F

· Naturally occurring oxide film on tantalum’s surface makes it resistant to corrosion in even the most severe acid environments and completely resistant to organic compounds.

· Assured end-product purity due to absence corrosion, scaling and flaking

· Faster validated cleanout between batches

· Maintenance free operation

· Long service life

· Excellent strength and durability, strength, and workability

Due to their much longer service life and maintenance free operation, tantalum heat exchangers are more cost-effective than equipment made from nickel-based alloys, impregnated graphite, or other materials. Because of its strength and workability, tantalum can be used in thin walled tubing for multipurpose helical coils, shell and tube heat exchangers, and bayonet heaters. This yields higher thermal efficiency, requiring less heat transfer surface. Thin sheets of tantalum can be clad in heating coils and tubesheet facings for the most cost-effective use of the metal.

The Rasmussen Company also supplies tantalum equipment for the pharmaceutical and chemical industries. We have assisted in the development of these major design benefits:

· Cross-contamination prevention. Tell-tale port construction acts exactly like double tubesheet designs to eliminate the possibility of cross contamination.

· Complete drainability. Flushmount tubesheet technology eliminates liquid hold-up, assuring complete drainability. Flush times are greatly reduced for increased productivity.

· Maintenance-free operation. Downtime and scrapped product are prohibitively expensive. The corrosion resistance of tantalum, and design features, such as silver-brazing tubesheet liners, virtually eliminates maintenance down time and equipment failure.

Tantalum is essentially acid-proof, except for hydrofluoric and fuming sulfuric acids. At temperatures under 300°F, it is inert to all concentrations of hydrochloric acid and nitric acid (including fuming), 98% sulfuric acid, 85% phosphoric acid, and to aqua regia. Tantalum is also completely inert to body fluids. In addition, it is fairly resistant to dilute alkaline solutions. Tantalum’s resistance to oxidation by various gases is also very good at low temperatures. Tantalum-tungsten alloys containing more than 18% tungsten are inert to 20% hydrofluoric acid at room temperature. These alloys are also somewhat more oxidation resistant than pure tantalum. They also appear to have the same corrosion resistance as pure tantalum.

Contact the Rasmussen Company to find out more about Tantalum.

Zirconium Heat Exchangers

The Rasmussen Company specializes in custom heat exchangers made from zirconium. They most commonly fabricate shell and tube type heat exchangers, but others types are available.

Zirconium exhibits great resistance to high-temperature water and steam. Zirconium also exhibits excellent resistance to most organic and mineral acids as well as alkaline solutions and alkalis. It is particularly useful in contact with sulfuric and hydrochloric acids. Zirconium equipment is suitable for processes that cycle between acidic and basic conditions, being corrosion resistant over a broad range of pH’s. It is also excellent when used in service with reducing environments. It is also immune to crevice corrosion in chloride solutions.

Contact the Rasmussen Company to find out more about Zirconium.

Impervious Graphite

The Rasmussen Company sells Graphite Block , Cubic , Shell & Tube Graphilor Heat Exchangers and Condensers. Phenolic and Teflon impregnated graphite resists acid attacks.

Silicon Carbide Ceramics

Silicon Carbide SIC Shell & Tube / Block

Silicon Carbide shell and tube heat / block Heat Exchangers utilize:

SIC advanced ceramic tubing, coupled with PTFE tube sheets and corrosion resistant o-rings

Silicon Carbide Machined and drilled stackable blocks and heads

SIC heat exchangers are an alterative technology in highly corrosive applications versus glass, graphite, or not-so-conductive teflon units.

Recommended process fluids include mixed acids, hydrofluoric acid, free halogens and caustics

The extreme hardness, high theoretical density, excellent strength properties, and absence of free silicon make SIC advanced ceramic inherently corrosion and erosion proof.

Extremely resistant to fouling.

• 100% resistant to thermal shock and erosion damage throughout its operating range.

• Designed and tested per ASME SEC VIII Div 1, TEMA, ANSI, ASTM