Elliptical Manways

Elliptical manways are self-energizing, or self-sealing, for an unlimited range of internal and external pressure applications. Manways are available in SA516gr70, SA105 Carbon Steel and 304 & 316 SA-240 / SA182 stainless steel

Rasmussen Company Inc. offers the following types of manways:

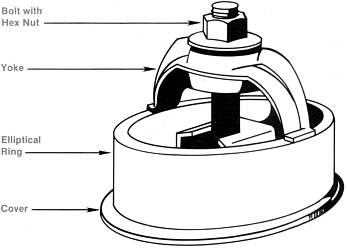

Yoke & Bolt Handholes/ Manways (standard applications)

The yoke & bolt manway provides the most economical pressure vessel access. As a self-energizing unit, yoke & bolt manways require positive internal pressures of at least 50 psi to achieve a seal. The standard yoke & bolt unit consists of a reinforcing ring, a pressed cover, one or two yokes (depending on type) with bolts and a gasket. Rings and covers are available in carbon steel or stainless steel.

Click here to view standard yoke & bolt manway dimensions and ratings.

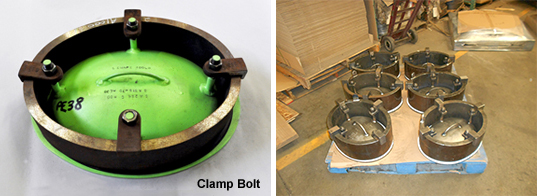

Clamp Bolt Manways (vacuum applications)

Clamp bolt manways are a low profile alternative to the yoke & bolt manway as well as a reasonably priced unit for vacuum applications. The standard assembly consists of a ring, pressed cover, clamps with bolts, and a gasket. Rings and covers are available in carbon steel or stainless steel .Click here to view standard clamp bolt manway dimensions and ratings.

Flat Machined Covers (for applications with pressures from 800 to 1000 psi)

Flat machined covers are made for pressures greater than basic yoke & bolt or clamp bolt manways can tolerate. These covers are available in standard thicknesses or in custom specified thicknesses that allow for a higher range of pressure / temperature conditions. Designed for use with yoke & bolt hardware. Covers are made of carbon steel (SA105, SA516gr70 PVQ Plate) and Stainless Steel.

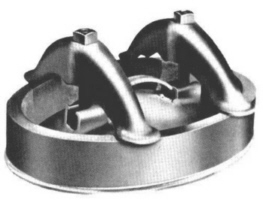

Bolt Plate Manways (for applications with pressures over 1000 psi)

Bolt plate manways are used for high pressure and vacuum service, in applications requiring hard gaskets (solid jacketed, spiral wound metal) or where severe external pressures exist. They can be designed for an unlimited range of internal and external pressures. The bolt plate sealing mechanics maintain constant sealing force, which makes these manways a good choice for vacuum applications. A standard bolt plate manway consists of an elliptical ring, a flat machined cover, a bolt plate, six stud bolts with hex nuts, and a gasket. The sealing mechanism works through the mechanical force applied by the designed bolts between the cover and the bolt plate (see illustration).

Bolt plate manways are custom designed for specific applications.

Elliptical rings are available either as seamless or ASME code welded. We will manufacture rings in standard or custom sizes based on your requirements. Rings can be made up to 12” thick by 20” length.

Each ring is formed, hot sized, and one edge faced for superior gasket sealing. Our elliptical rings are furnished to SA106-Gr.B/C / SA105N /SA516gr70/ SA675gr70 / SA240 Stainless Steel.

Click here for required elliptical ring depths for different sized vessels and manways.

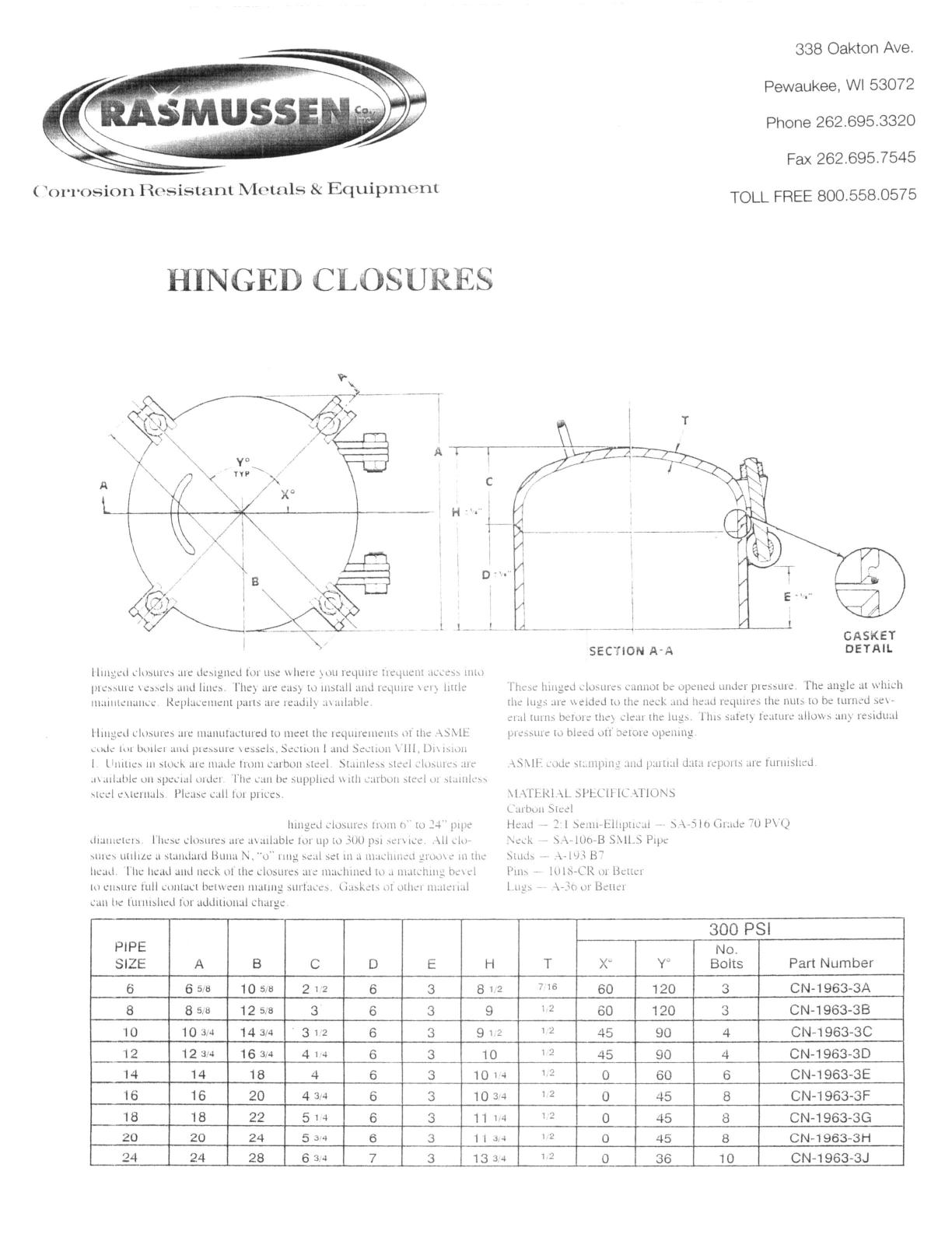

T-Bolt Hinged Closures

Hinged closures are designed for use where you require frequent access to pressure vessels and lines. They’re easy to install and require very little maintenance/ Replacement parts are readily available.

Hinged closures are manufactured to meet the requirements of the ASME code for boiler and pressure vessel, Section I and Section VIII, Division I. Units in stock are made from carbon steel. Stainless Steel closures are available on special order. They can be supplied with carbon steel or stainless steel externals. Please call for prices.

Rasmussen provides hinged closures for 6″ to 24″ pipe diameters. These closures are available for 300 PSI service. All closures utilize a standard Buna N O-ring seal set in a machined groove in the head. The head and neck of the closures are machined to a matching bevel to ensure full contact between mating surfaces. Gaskets of other material can be furnished for an additional charge.

These hinged closures cannot be opened under pressure. The angel at which the lugs are welded to the neck and head requires the nuts to be turned several turns before they clear the lugs. This safety feature allows any residual pressure to bleed off before opening.

ASME code stamping and partial data reports can be furnished if requested at the time of ordering.

Material Specifications –

Carbon Steel

Head – 2:1 semi-elliptical – SA516 Grade 70 PVQ

Neck – A-53-B or A-106-B SMLS pipe

Studs – A-193 B7

Nuts – A-194 2H

Pins – 1018-CR or better

Lugs – A-36 or better

Gaskets

The Rasmussen Company offer gaskets in a wide variety of materials for use with round or elliptical manways.

Below are descriptions of available gasket materials:

Expanded PTFE

PTFE adhesive backed gaskets are strong and tough, yet soft, allowing them to conform to any surface. They compress to a thin, wide ribbon under pressure. PTFE gaskets do not deteriorate with age, are unaffected by many chemicals, tolerate temperatures up to 650° F and pressures of 3000psi, and will not contaminate flow products. In addition, PTFE’s non-stick characteristics allow easy manway opening.

Peel away adhesive backing makes installation simple.

Buna-N Buna-S

This is a well known plastic material that can be used in environments up to 250° F.

Black Neoprene

This is a synthetic rubber gasket material useful for certain process applications. It can tolerate temperatures up to 200° F.

Spiral Wound

This is a flexible metal gasket material for use in high pressure, high temperature situations.